-

MA Xiuliang Title:professor Email: xlma@imr.ac.cn Tel. : +86-24-23971845 FAX: 024-23891320 Division: Shenyang National Laboratory for Materials Science Address: Solid Atomic Imaging Division, Institute of Metal Research Chinese Academy of Sciences (IMR CAS), 72 Wenhua Road,Shenyang,China., 110016

Experience: |

|

Graduated in 1988 at Department of Materials Engineering, Dalian University of Technology (DUT), Dr. Ma received his Ph.D in 1994 under the supervision of Professor K. H. Kuo at DUT and Beijing Laboratory of Electron Microscopy. He received the Research Fellowship in 1995-1997, in 2002, and in 2005, from the Alexander von Humboldt Foundation, Germany, and Fellowships in 1997-2001 from Japan Fine Ceramics Center, Tokyo University, and the City University of Hong Kong, respectively. |

Research Interest: |

|

Atomic imaging and spectrometry of condensed matters |

Research Achievement: |

|

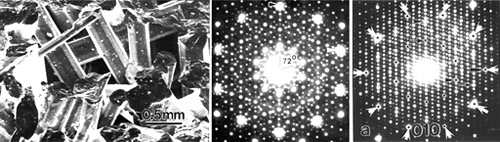

Quasicrystals and related crystalline approximants in Al-alloys Discovered the first binary system in which stable decagonal quasicrystal (DQC) is obtained, this work changed one’s concept that stable DQC could be obtained only in multicomponent alloys; Successfully grown millimeter-scaled single-crystallined DQCs, and obtained the physical properties which are remarkably different from those of conventional 3D periodic crystals; Discovered 13 new phases with giant unit cells in Al-Co alloys and 7 new phases in Al-Cu-(Cr) system, classified these phases into two families of monoclinic and orthorhombic, established relationships among all these phases and proposed the structural models for some of them.

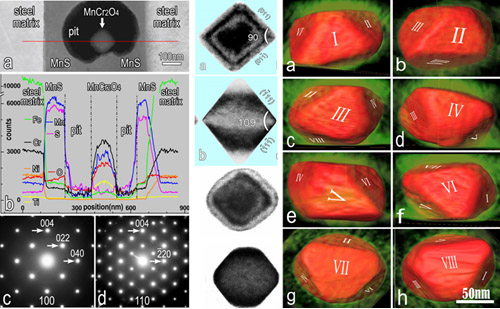

Figure 1. Millimeter-scaled single crystals of Al-Co DQC and its crystalline approximants identified by scanning electron microscopy and transmission electron diffraction patterns Spinel nano-octahedron catalysing local dissolution of MnS in stainless steels Stainless steels are actually not “stainless”; in the presence of aggressive anionic species they are susceptible to the localized pitting corrosion that is one of the major causes of materials’ failure and hence leads to a huge loss to our society. The pitting event is generally believed to originate from the local dissolution in MnS inclusions which are more or less ubiquitous in stainless steels. Nevertheless, the initial location where MnS dissolution preferentially occurs is known as unpredictable, which makes pitting corrosion remain a big headache in engineering. We have chosen some commercial stainless steels and performed a symmetric transmission electron microscopic study. We found nano-sized octahedral MnCr2O4 crystals embedded in the MnS medium, generating local MnCr2O4/MnS nano-galvanic cells. The TEM experiments combined with first-principles calculations clarified that the nano-octahedron, enclosed by eight {111} facets with metal terminations, is “malignant”, which acts as the reactive site and catalyzes the dissolution of MnS. This study uncovers the origin of MnS dissolution in stainless steels and provides a new basis for understanding pitting corrosion of stainless steels. The present findings are of great importance for steel-making industry by calling for the attention to nano-inclusions whose presence and function are neglected ordinarily. This work is expected to draw attention of material scientists, chemists, and biomedical workers to a general concern that the phenomena similar to the one in this study may occur in a wide range of engineering alloys and biomedical materials/instruments serving in wet environments.

Figure 2. 3D tomography showing the configuration of the spinel MnCr2O4 nano-octahedron around which MnS dissolution in stainless steel occurs in the presence of salt water. |

Service to the International Professional Societies: |

|

Editorial Board members of Progress in Natural Science --Materials International; a member of Editorial Board of Materials Letters; a member of the council of Chinese Electron Microscopy Society; and the executive vice-president of Electron Microscopy Society, Liaoning province. |

Honors: |

Publication: |

Homepage: |