-

ZENG You Title:Professor Email: yzeng@imr.ac.cn Tel. : +86 24 8397 8090 FAX: +86 24 23891320 Division: Shenyang National Laboratory for Materials Science Address: Advanced Carbon Division, Institute of Metal Research Chinese Academy of Sciences, 72 Wenhua Road, Shenyang, China, 110016

Experience: |

|

1993 Wuhan University of Technology, bachelor of engineering 1996 Wuhan University of Technology, master of engineering 2004 Institute of Metal Research, Chinese Academy of Sciences (CAS), Ph. D. 1996-1998 Shenyang Jianzhu University, assistant professor. 1998-2003 Shenyang Jianzhu University, lecturer 2003-2008 Shenyang Jianzhu University, associate professor 2008-2008 Rice University, visiting scholar 2009-2012 Shenyang Jianzhu University, professor 2012 Institute of Metal Research, CAS, Professor |

Research Interest: |

|

Carbon nanotube & graphene-based composites, polymeric composites, and advanced functional composites. |

Research Achievement: |

|

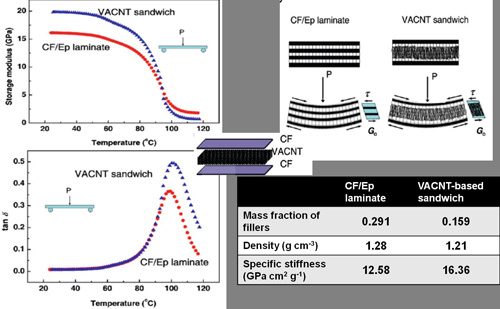

(1) Design and Reinforcement: Vertically Aligned Carbon Nanotube-Based Sandwich Composites To obtain composites with high rigidity and damping, we have designed and fabricated VACNT-based sandwich composites from simply stacking the freestanding VACNTs and CF fabrics and infiltrating with epoxy matrix. Comparing with the CF/epoxy laminates, the VACNT-based sandwich composites exhibit higher flexural rigidity and damping, which is achieved due to the effective integration of the VACNTs as an interfacial layer between the CF stacks. Furthermore, the lighter weight of these VACNT-based sandwich composites offers advantages in aerospace and transportation applications. (Figure 1)

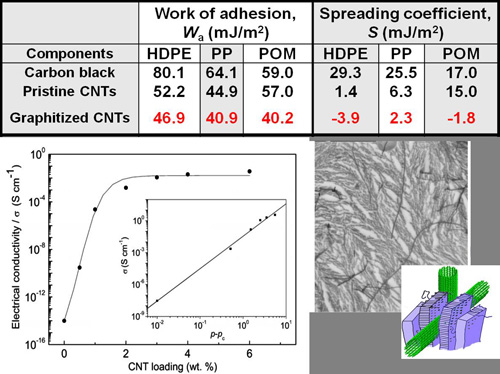

Figure 1. Dynamic mechanical analyses of the carbon-fiber/epoxy (CF/Ep) laminate and the vertically-aligned carbon nanotube (VACNT) sandwich in a three-point bending mode, revealing that the VACNT sandwich (blue triangle) exhibits higher storage modulus and better damping properties (higher energy dissipation during cyclic deformations) than the CF/Ep laminate (red circle) due to the vertical alignment of CNTs and the resulting remarkable reinforcement of shear modulus. Moreover, the VACNT sandwich exhibits lower mass fraction of fillers, lower density, and higher specific stiffness than the CF/Ep laminate. (ACS Nano 2010, 4, 6798-6804) (2) Increasing the electrical conductivity of carbon nanotube/polymer composites by using weak nanotube–polymer interactions A weak interaction between carbon nanotubes (CNTs) and polymers was found to reduce polymer-wrapping on CNT surface, decrease the contact resistance between CNTs, and increase the electrical conductivity of their composites. It was found that the graphitized CNTs filled polyoxymethylene (POM) system exhibits the weakest CNT–polymer interaction among all the investigated systems and a poor wettability. Consequently, the graphitized CNT/POM composites possess a high electrical conductivity and a low percolation threshold of 0.5 wt.% CNT loading, which is associated with the weak CNT–polymer interaction, low contact resistance between CNTs, good connectivity of CNT networks, and high crystallinity of POM in the composites. The results obtained imply that high-performance composites with optimal CNT-network structures can be designed and fabricated by fully considering the surface properties of components and CNT–polymer interactions. (Figure 2)

Figure 2. Weak interactions between the graphitized CNTs and polymer, resulting in the unwrapped-CNTs existing among micro-fibrils of polymer spherulites and consequently the low percolation threshold of 0.5 wt% for the CNT/polyoxymethylene composites. . ( Carbon 2011, 48, 3551-3558.) |

Service to the International Professional Societies: |

|

Reviewer for international journals: Carbon, Composite Science & Technology, ACS Applied Material & Interfaces, Express Polymer Letters, Journal of Materials Science, Journal of Applied Polymer Science, etc. |

Honors: |

Publication: |

|

[1] Y. Zeng, L. J. Zhao, W. Wu, G. Lu, F. Xu, Y. Tong, W. Liu, J. Du. Enhanced adsorption of malachite green onto carbon nanotube/polyaniline composites. Journal of Applied Polymer Science, Online, DOI:10.1002/app.37947 (2012) [2] Y. Zeng, H. S. Liu, J. Chen, H. Y. Ge. Effect of strain on the electrical resistance of carbon nanotubes/silicone rubber composite. Journal of Wuhan University of Technology-Materials Science Edition, 26(5): 812-816 (2011) [3] R. K. Srivastava, V. S. M. Vemuru, Y. Zeng, R. Vajtai, S. Nagarajaiah, P. M. Ajayan, A. Srivastava. The strain sensing and thermal–mechanical behavior of flexible multi-walled carbon nanotube/polystyrene composite films. Carbon, 49: 3928-3936 (2011) [4] J. H. Du, L. Zhao, Y Zeng, L. L. Zhang, F. Li, P. F. Liu, C. Liu. Comparison of electrical properties between multi-walled carbon nanotube and graphene nanosheet/high density polyethylene composites with a segregated network structure. Carbon, 49(4): 1094-1100 (2011) [5] Y. Zeng, L. Ci, B. Carey, R. Vajtai, P. M. Ajayan. Design and reinforcement: vertically aligned carbon nanotube-based sandwich composites. ACS Nano, 4(10): 6798-6804 (2010). [6] Y. Zeng, P. F. Liu, J. H. Du, L. Zhao, H. M. Cheng. Increasing the electrical conductivity of carbon nanotube/polymer composites by using weak nanotube–polymer interactions. Carbon, 48: 3551-3558 (2010). |

Homepage: |